News Update - AVRGT January 24

AVR Global Technologies, Inc focused in custom molded cables, wire harness and electronic assemblies news update:

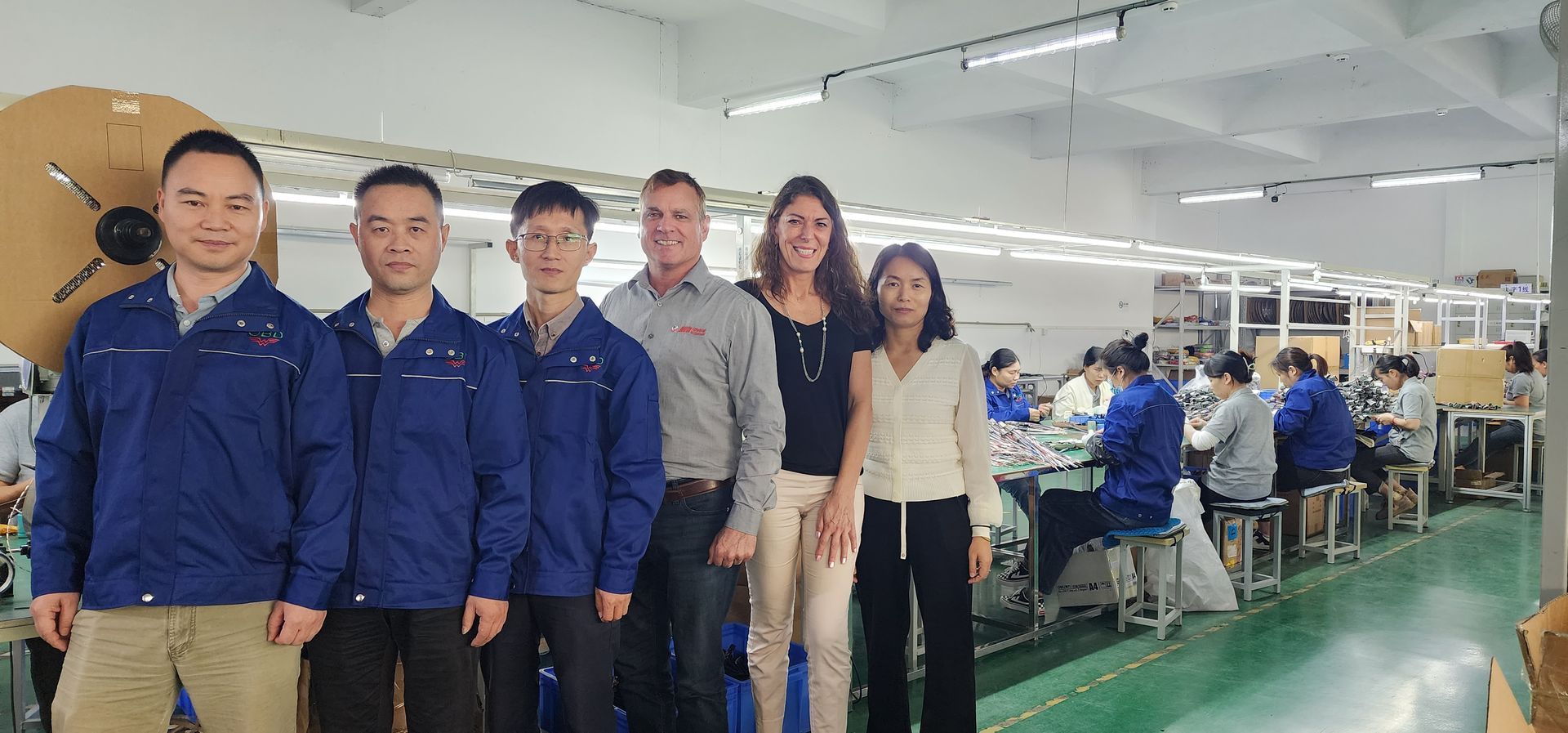

Expanding 2X Manufacturing – Shenzhen, China. Due to current and new customer growth; AVRGT staff visited our Shenzhen manufacturing plants and staff in December 2023. Key decisions were made to expand operations by 2X with a new building and 50% more Mfg/Tech staff to prepare for 2024-2025 growth. Included to new staff, we expanded manufacturing operations space by 10,000 SQ FT and 2X more cable Mfg equipment.

IP67 Certification Testing. The Engineering staff conducted full IP67 testing on our engineered water-proof over-molded cables, used in military/police/para-military applications ( MRAP and SWAT type vehicles ) that required high-level IP66, IP67, IP68 certified testing. Test results were 100% Pass IP67 approved and additional approvals for IP66. The AVRGT cables passed 100% in ruggedized testing, beyond expectations. The cables now go into full 2024 production with custom over-molded connectors that will be used in MRAP and similar heavy vehicle applications.

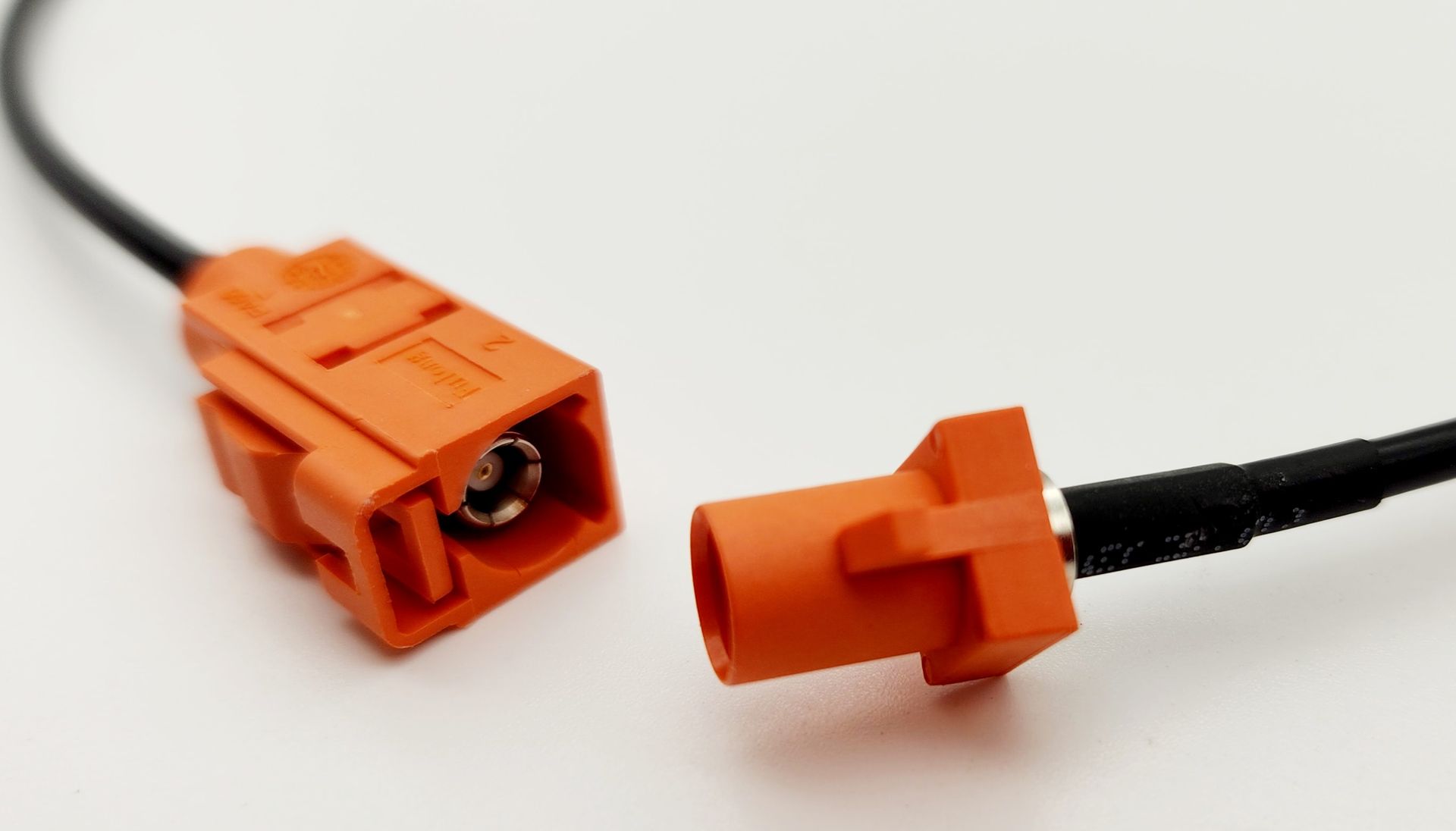

FAKRA – COAX – RF Cables. The Engineering team released new application design cable with FAKRA brand coaxial connectors, used in sophisticated high-speed data/video applications. Applications including Telematics and Vehicle video / data collection. In standard, dual and quad-connector and Splitter applications. Typical RF Coaxial cable sizes used with AVRGT FAKRA connectors include: RG174, RG179, RG59, RG6, RTK031. There are 14 combinations (clocking types by alpha-color code) (A, B, C, D, E, F, G, H, I, K, L, M, N, Z).

See the new product pages.

3D Print Farm & CNC Operations Expansion.

AVRGT Engineering staff have agreed to expand our 3D Printing operations here in our San Marcos, California 92069 operations plant. Including, water and laser type CNC machines for customer engineering R&D applications. The potential for 3D printing farm jobs will have up to 1,000 items per day, with up to 30 3D high-speed advanced-modern 3D printers. Both-jet and laser CNC machines are now being purchased for operations. This program will be fully released for customer deployments in 2024.