Advanced 3D Printing

Unlock faster lead times, enhanced precision, and fully customized cable solutions with AVR Global Technologies advanced 3D printing capabilities. Designed to support complex OEM supply chain demands, our technology delivers exceptional quality, flexibility, and performance built to meet your exact specifications.

Advanced 3D Printing Solutions

Leverage cutting-edge 3D printing technology to enhance the design, customization, and manufacturing with precision and efficiency.

Precision Customization

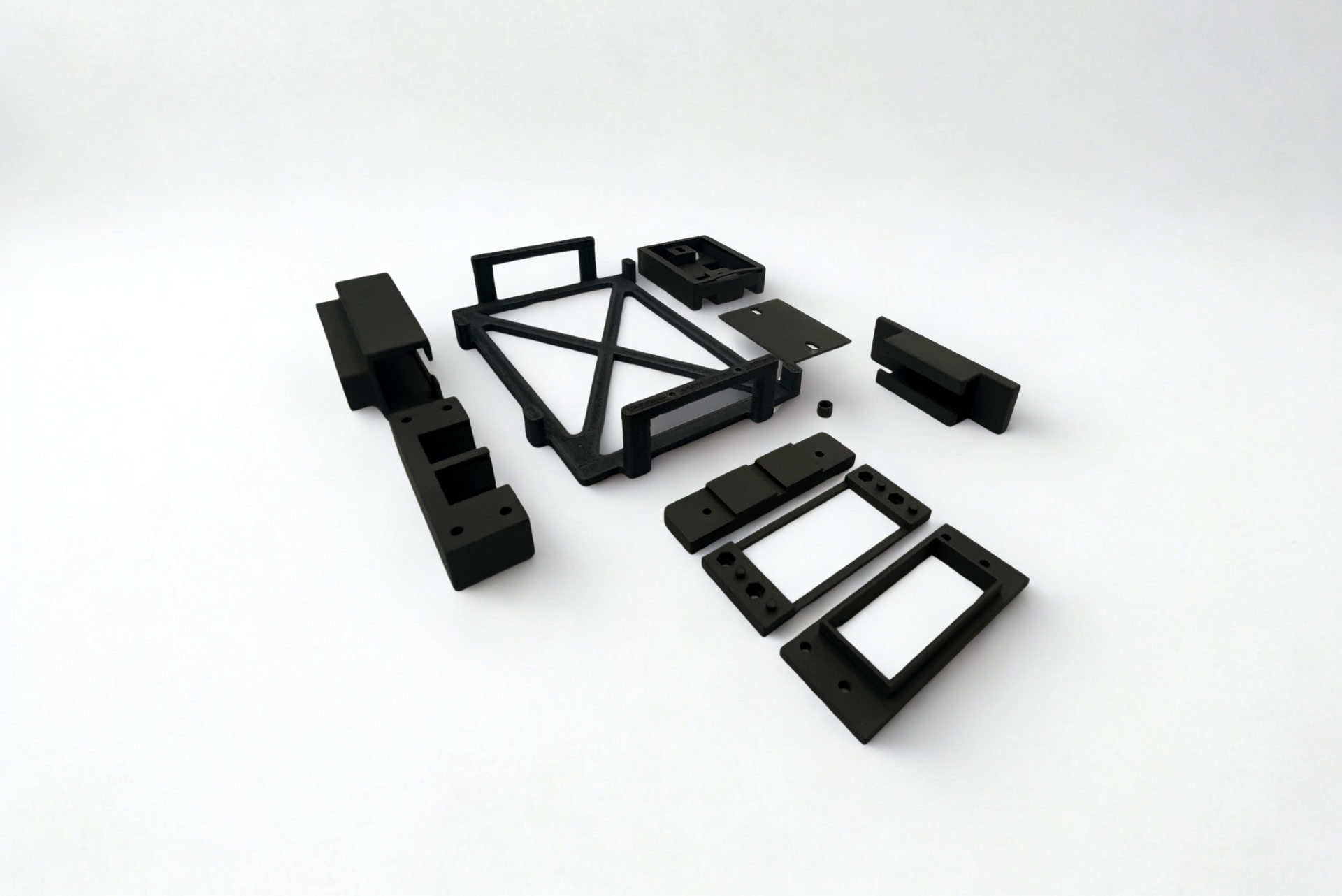

Our 3D printing technology provides customized solutions that cater to the unique demands of OEMs.

Rapid Prototyping

Accelerate product development cycles with fast turnaround times, allowing quick iterations and faster time-to-market.

Material Versatility

Utilize a wide range of durable materials compatible with 3D printing to produce cables that withstand demanding environments.

Enhanced Production Efficiency

Integrate 3D printing into your supply chain to reduce waste, lower costs, and improve overall manufacturing efficiency.

Innovative 3D Printing Solutions

Explore Our 3D Manufacturing Technologies

3D Printing FAQs

Find answers to common questions about our advanced 3D printing services and how they enhance custom molded cable production.

What 3D printing technologies do you use?

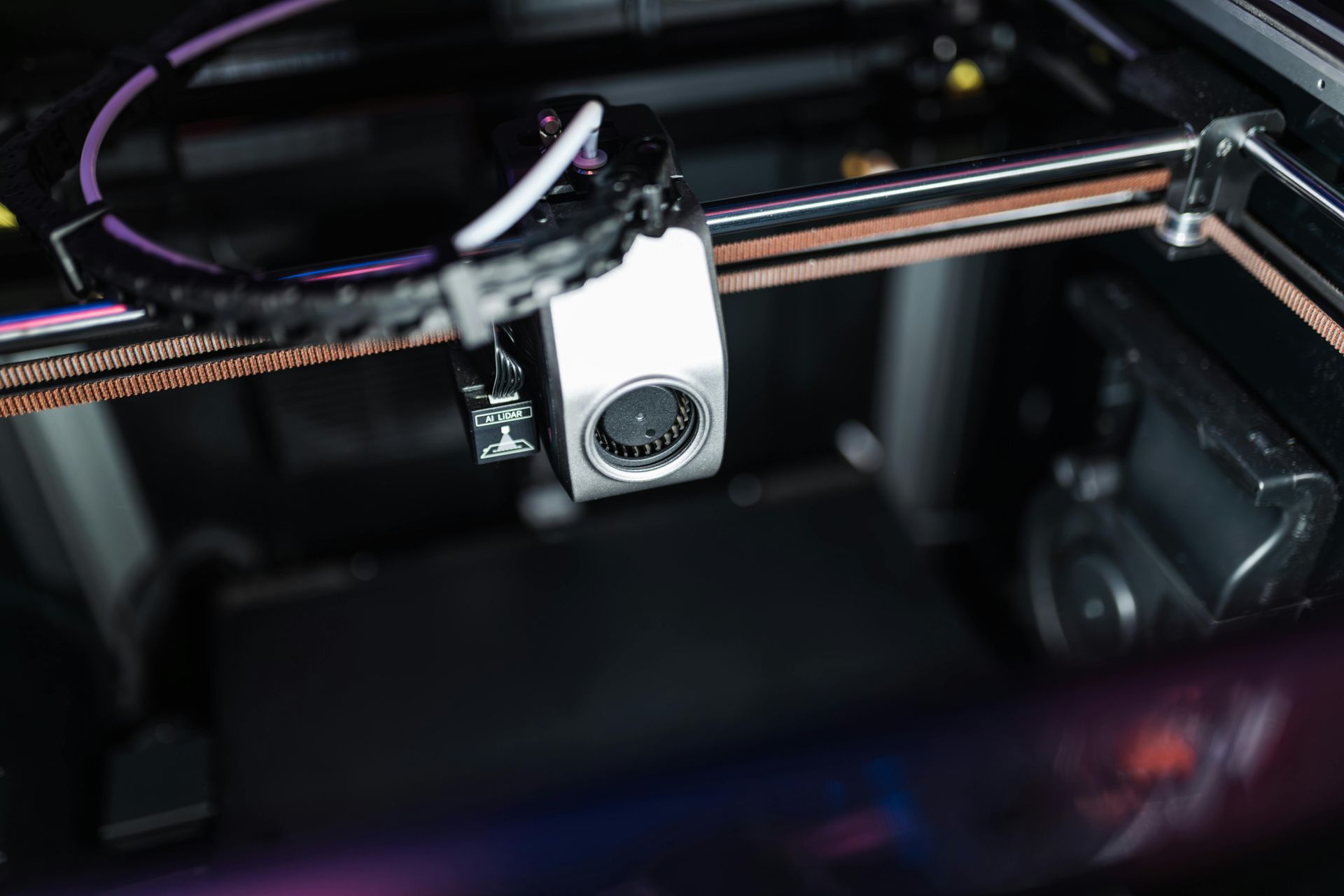

At AVR Global Technologies, we utilize four types of 3D printing technologies to meet a wide range of engineering and manufacturing needs:

Low-Temp FDM (Fused Deposition Modeling): Ideal for fast, cost-effective prototyping using materials like PLA and PETG.

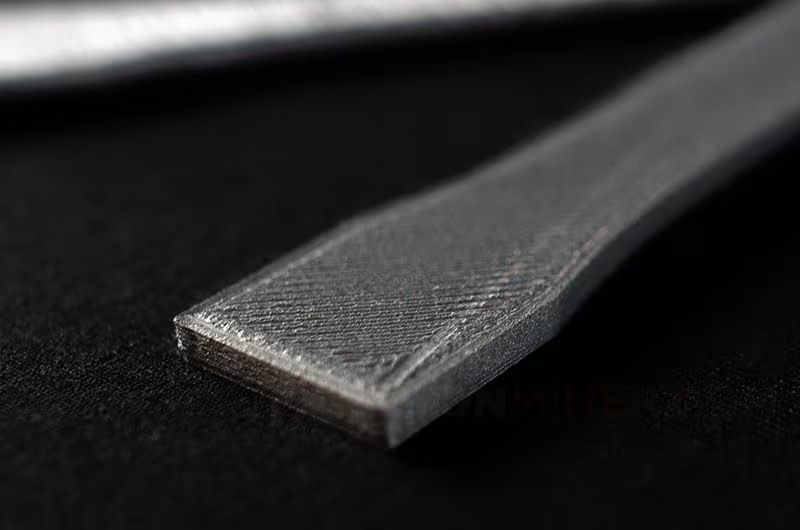

High-Temp FDM: Designed for performance-grade parts with materials such as ABS, ASA, and carbon fiber-reinforced filaments great for durable, functional components.

Laser SLS (Selective Laser Sintering): Delivers strong, production-quality nylon parts with excellent mechanical properties, perfect for end-use applications.

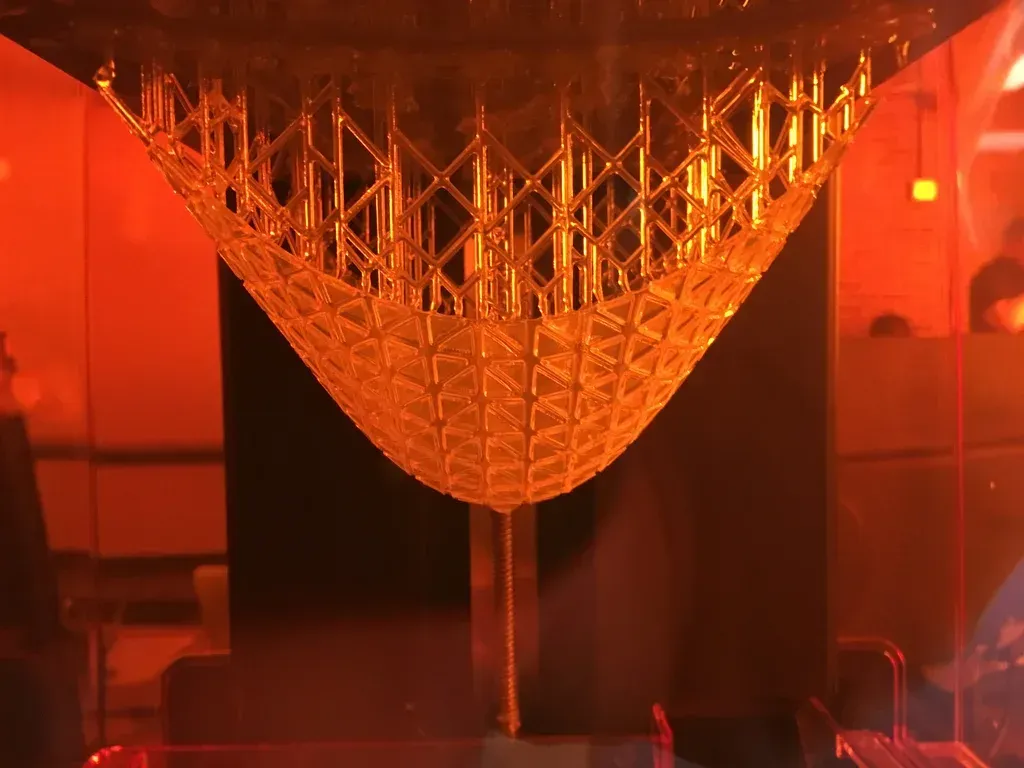

Resin SLA (Stereolithography): Provides high-resolution parts with smooth surface finishes especially useful for tight-tolerance prototypes and fine-detail pieces.

This range allows us to tailor our process to each project’s unique requirements, whether it's strength, speed, detail, or material compatibility.

Which materials are available for 3D printing?

Our 3D printing supports a range of engineering-grade plastics and resins optimized for electrical insulation and mechanical strength.Can 3D printing be customized for specific cable designs?

Yes, we tailor 3D printed parts to exact specifications, enabling complex geometries and integrated features for OEM cable assemblies.What are typical lead times for 3D printed parts?

Lead times vary by project complexity but generally range from a few days to two weeks, supporting rapid prototyping and production.How do you ensure quality in 3D printed components?

We apply rigorous inspection protocols and material testing to guarantee dimensional accuracy and performance compliance.

Is 3D printing integrated with your OEM supply chain services?

Absolutely, our 3D printing seamlessly complements our OEM manufacturing, procurement, and logistics for efficient end-to-end solutions.Can 3D printing scale for large production runs?

While ideal for prototyping and small batches, we also support scalable production through optimized workflows and hybrid manufacturing.What support do you offer for 3D printing projects?

Our engineering team provides design consultation, material selection guidance, and ongoing technical support throughout your project.How do I start a 3D printing project with AVR GLOBAL TECHNOLOGIES?

Contact us via our inquiry form or phone to discuss your requirements and receive a tailored proposal.Can 3D printing reduce costs in cable manufacturing?

By enabling rapid prototyping and reducing tooling needs, 3D printing can lower development costs and accelerate time to market.

| Material (process) | Water | UV | Oil/Fuel (gasoline/diesel) | High-Temp (°C, continuous) | Cold-Temp toughness | Strength/Stiffness | Flexibility |

|---|---|---|---|---|---|---|---|

| PLA (FDM) | Fair | Poor | Poor | 50–60 | Poor | Fair | Low |

| ABS (FDM) | Fair | Poor | Fair | 80–90 | Fair | Good | Low |

| ASA (FDM) | Good | Excellent | Fair | 90–100 | Fair | Good | Low |

| PETG (FDM) | Excellent | Good | Fair | 70–80 | Fair | Good | Low–Med |

| PC (FDM) | Good | Fair | Poor–Fair | 110–120 | Good | Excellent | Low |

| Nylon PA12 | Good* | Fair | Good | 90–120 | Excellent | Excellent | Med |

| Nylon + CF (FDM) | Good* | Fair | Good | 110–130 | Good | Excellent | Low–Med |

| PP (FDM) | Excellent | Fair | Excellent | 90–100 | Good | Fair | Med |

| TPU 95A (FDM) | Excellent | Fair–Good | Good | 70–80 | Excellent | Low | Excellent |

| PEEK (FDM) | Excellent | Fair | Excellent | 240–260 | Excellent | Excellent | Med |

| PEI/Ultem (FDM) | Excellent | Fair | Good–Excellent | 160–180 | Excellent | Excellent | Med |

| PPSU (FDM) | Excellent | Fair | Excellent | 180 | Excellent | Excellent | Med |

| SLA Tough Resin | Fair | Poor | Poor–Fair | 60–70 | Poor–Fair | Med | Low |

| SLA High‑Temp Resin | Fair | Poor | Poor–Fair | High HDT | Poor | High (brittle) | Low |

Ready to innovate with 3D printing?

Connect with our experts to explore how 3D printing can enhance your custom projects.